Last Updated on July 24, 2022

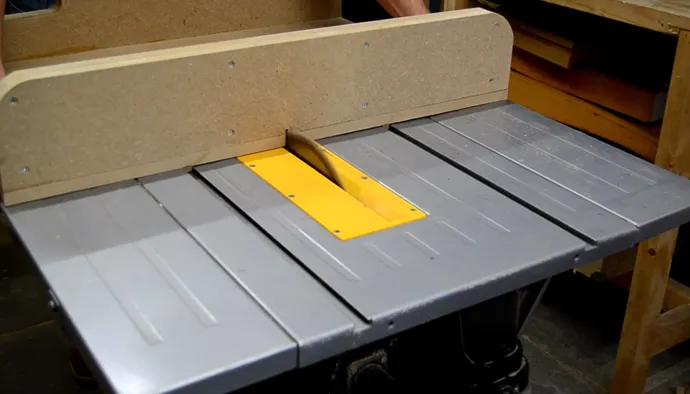

When buying a table saw, you might be wondering, is MDF good for table saw sleds? The good news is that it is affordable, flat, and a relatively reliable material.

However, there are some disadvantages to MDF sleds, including the fact that they make a mess while sawing. This article will look at a few advantages and disadvantages of MDF for table saw sleds, as well as how to mount them properly.

mdf is cheap, flat, and reliable

MDF is a very cheap, flat, and reliable table saw sled material. It has a very low coefficient of friction and is self-lubricating. You will also find that it will not leave shavings or residue behind.

It also has a very durable finish, and it weighs about 10 times as much as regular high-density polyethylene. Unlike wood, MDF won’t expand or contract in any way due to exposure, and it has exceptional impact strength.

A table saw sled’s front and rear fences are typically made from solid hardwood. These fences will not be as stable over time.

An alternative to solid hardwood is a sled that is made as a sandwich with top and bottom pieces made of 1/2″ plywood and middle layers made of MDF. It is also a good idea to look for a sled with threaded inserts instead of wood.

Choosing a table saw sled material is important because you will need to use it often. Luckily, there are many inexpensive, flat, and reliable materials you can use.

MDF is a cheap, flat, and reliable material for your sled. Just be sure to check the material’s flatness before you buy it. A good quality table saw sled can make perfect 45-degree miter cuts with ease.

You’ll also find cheap, flat, and reliable MDF at Woodcraft. A sheet of 1/2″ MDF will cost you under $20. If you need a thicker piece, you may have to spend more than $50, but the benefits of MDF are priceless. It’s also flat and cheap to ship. A little bit of MDF goes a long way.

It makes a mess to saw

Adding a miter sled to your table saw is a great way to cut perfectly matched miters. Half sheet of plywood or 3/4-inch particleboard work well, as does MDF. You can also use full paint cans to make a miter sled. This sled is also great for cutting large panels, but make sure to follow the manufacturer’s instructions carefully.

You can find MDF at Woodcraft for less than a dollar a sheet. It should not be too expensive and shipping should not cost much. It’s cheap and reliable, but it’s a bit messy to saw MDF, and you’ll need to mask and DC to get a straight cut. If you’re worried about splinters, get a table saw sled made from aluminum.

Using a table saw sled makes long projects easier and safer. It also gives you a guide for making repeatable cuts. The table saw sled also makes long projects with precise measurements easier to complete. Once you’ve stacked the material, you can set the table saw sled and start cutting! Then, you can see how quickly you’ll finish your project!

If you need to make an angled or miter cut, a table saw sled can help you get the precise cut. The table saw sled also allows you to make crosscuts and other shapes with ease. The table saw sled eliminates the need for sliding fences. They can also be used with other jigs. In addition to these, you’ll need a miter jig.

It stabilizes the work piece

MDF is a very common material used for a table saw sled. It is lightweight and stable, and it is also an excellent option for table saw sleds that require accurate measurements.

The material also offers some benefits, including accuracy and ease of use. This article will discuss some of the benefits of MDF for table saw sleds. The following information will help you make the best decision for your needs.

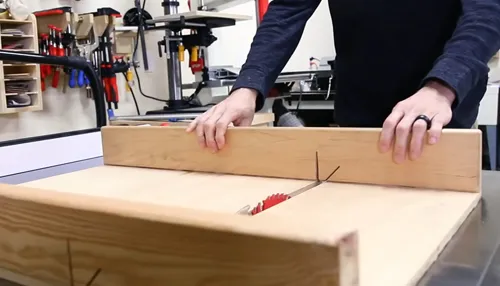

To install a table saw sled, you must first assemble the sled. This includes clamping the front and rear fences to the base of the table saw.

You should also pre-drill holes in the front fence for the screws that attach the sled to the table. After the screws are in place, you should add glue to the sled and base and wait about an hour before using the saw.

To make a table saw sled, first cut a slab of MDF into a 24 x 18-in. rectangle. Next, cut the runners to the correct width and thickness. The runners should protrude about 1/8 of an inch above the table.

Sand the runner pieces until they glide smoothly in the slots. This step is very important to ensure an accurate sled.

The sled is easy to use. Measure the length of the pen barrel from the stop and place it in the sled. Loosen the wing nut that is located in the slot and tighten it.

You can use a toggle clamp to hold the piece in place and adjust the sled to fit the length. There are also many options for table saw sleds available in the market.

It’s easy to mount

One of the easiest ways to mount a sled on a table saw is to cut MDF or plywood to the right size. Then, you can cut a 45 degree angle on one end of the material so that it fits into the miter slot.

It takes about 45 seconds to assemble the sled, and it can be taken down just as easily. A table saw sled makes the work easier by eliminating the need for complicated attachments, and it also allows the sled to be moved from one location to another.

MDF is easy to mount for a table saw sled because of its low cost and versatility. You can purchase 1/2″ x 12″ pieces from Woodcraft for $1.99 and 3/4″ for $6.29.

These are relatively cheap and should not cost much to ship. You’ll need to mount the MDF pieces with a DC power supply and a mask. You can also make your own miter gauge sled by following a DIY kit.

After you cut the MDF strips, you’ll need to glue or nail them to the MDF base. Then, attach the MDF runner to the MDF spacer. Once the runner is secure, you’ll attach the sled to the base of your table saw.

If you’re having trouble installing the runner, check out this article. It’ll show you how to install your sled in a few simple steps.

Using a table saw sled is easy if you’ve mounted one yourself. Most table saws have a blade off-center between the miter bars, which makes mounting the sled difficult.

MDF is easy to mount for table saw sled, and you can make your own sleds to fit specific uses, such as 45deg miter sleds for picture frames.

It’s adjustable

Adjusting a table saw sled is a relatively simple process. First, cut a piece of MDF that’s 1/4″ wider than the sled’s blade. Line the template up with the edge of the miter slot on the base of the sled. Then, add glue to the runner. Clamp the template and runner to the base. Nail it into place.

You can also use MDF as a sled or as a runner. Using a 3/4″ MDF piece, slice it in half and place the screw in the middle. Be careful not to glue it to the sled, as it won’t hold for long. This will ruin the edges of the runner. You can use the other half of the piece for a miter slot or runner.

The sled base is made of a slab of MDF cut to 24 by 18 inches. Next, you’ll need to cut the runner pieces to the proper thickness. They should project 1/8 of an inch over the table. You should also rip the runner pieces so that they slide smoothly into slots on the sled base. The runner is the main component of an accurate sled.

The next step in setting up your table saw sled is to cut a piece of MDF using a test piece. Using carpet tape, attach the MDF to the fence and sled base. Then, flip over the cut piece, check the fit of the edges. If the edges fit snugly, the sled is properly set up. If not, it’s time to adjust the fence.

Frequently Asked Questions (FAQs)

What is MDF?

MDF is a type of engineered wood that is made from heat-pressed wood fibers. It is a popular choice for making furniture, cabinets, and other woodworking projects because it is very smooth and has a consistent texture.

MDF stands for medium-density fiberboard. It is an engineered wood product made by breaking down hardwood or softwood residuals into wood fibers, combining it with wax and a resin binder, and pressing it into sheet form.

How is MDF different from particle board?

MDF is different from particle board in several ways. First, MDF is made from wood fibers, while particle board is made from wood chips. Second, MDF is denser and harder than particle board. Finally, MDF is smoother and has a more consistent surface than particle board.

MDF is denser than particle board and has a smoother surface. It is also free of the voids and large particles found in particle board.

What are the advantages of using MDF for a table saw sled?

MDF is a very stable material, so it is ideal for using as a table saw sled. It is also easy to work with and can be given a very smooth finish.

Conclusion

MDF is a good material for a table saw sled because it is flat, smooth, and consistent. It is also inexpensive and easy to find.