Last Updated on July 24, 2022

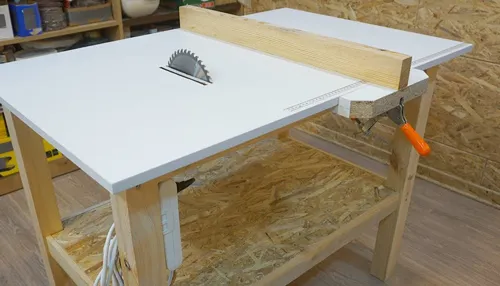

If you are interested in building cabinets, you will want to purchase a table saw. There are two types of table saws: infeed and outfeed. Infeed and outfeed tables allow for fast cuts and are a necessity for cabinet makers.

Read on to find out what type of saw you need and how to choose one. In this article, we’ll also discuss some safety concerns. You can’t cut through metal if you’re not careful, so take precautions with this piece of equipment.

Getting a cabinet table saw

When purchasing a cabinet table saw, there are many different things to look for. One of the most important features is the fence, which helps you make precise cuts while keeping the saw blade from moving.

You should also check the fence’s straightness and make sure it doesn’t have any warps or curves. This is especially important if you plan to use the saw for a long time. Below are some tips for choosing the best cabinet table saw for your needs.

First and foremost, you’ll want to purchase a saw that’s powerful enough to cut the wood you’ll be cutting. Most cabinet table saws have a motor ranging from 3 to 7.5 horsepower.

Though some may think that 7.5 horsepower is overkill, this type of machine is worth the extra money. The blade will need to be sharp to cut through softwood, so you need a blade that will allow for that.

Another important feature to consider is the table’s size. Compared to other cabinet table saws, this one’s table is moderately sized. It also has a strong, 64-inch table rail that will minimize vibration.

A poly-V belt drive system under the cabinet will reduce vibration and make accurate cuts easier. This saw can cut up to 50 inches at a time. There are some pros and cons to using a cabinet table saw, but these are the most important features to look for.

A cabinet table saw is more substantial than a benchtop one. This makes it a good choice for those looking to expand their woodworking production.

Typically, cabinet table saws have 50-inch rip capacities, enclosed bases, and two extra legs at the end of the extension table. When buying a cabinet table saw, keep in mind that it’ll need space to work in. Also, be sure to choose the right size for the space in your workspace.

One of the most important features to consider when purchasing a cabinet table saw is safety. Safety is paramount and a cabinet table saw with a safety system will protect your hands and prevent any accidents.

With an on-board computer, safety features, and great extras, a cabinet table saw can be an excellent choice for your woodworking needs. One thing to keep in mind, however, is the price. Most cabinet table saws are quite expensive, so you’ll need to decide based on the features you need in your specific situation.

Using a table saw to build cabinets

When using a table saw to build cabinets, it is crucial to find the best blade for the job. While many brands feature thinner bases, they are fine for general cutting. You should look for a saw that has a cast magnesium base for excellent stability and light weight.

This type of blade also provides better cutting speed, and is less likely to tear or chip wood. But this doesn’t mean that you should forgo a good quality table saw just because you want to use it for cabinet making.

When buying a table saw, there are several things to keep in mind. There are many different types and models available, and you can customize your choice to suit your needs.

Consider blade size, power rating, portability, design, and experience level. Also consider the materials you plan to work with. Some saws are more versatile than others, and can be used for various materials. However, a table saw that has an integrated platform is most effective for building cabinets.

Another important feature of a good table saw for cabinet making is its safety features. For example, the SawStop PCS175-TGP252 comes with a safety system that detects skin and stops the blade for five milliseconds when it contacts it.

In addition to that, it also comes with a protective guard. The blade is protected by a protective guard, which lifts as the workpiece is pushed into the blade.

The type of materials you can cut will depend on the size and power of the saw. The maximum depth of cut will depend on the motor power of the saw, while its weight and size will determine how easy it is to move around.

Also, when purchasing a table saw, consider the type of base. Table saws with more rip capacity can be more expensive, so it’s better to choose one with a smaller rip capacity.

A good table saw is a great tool for cabinet building, but you don’t want one that’s too expensive and too large.

You can buy a cheaper, budget-friendly version if you want a table saw for cabinet building but you won’t get the same precision or cutting quality from a more expensive model. There are many table saws on the market, so choose the best one for your needs.

Choosing a table saw

Choosing a table saw for cabinet building is one of the first things you should do. These machines are power tools and are usually measured in Horse Power (HP). In addition to durability, table saws should also have the necessary safety features.

These can include blade covers, emergency stop buttons, and conductive braking systems. Moreover, choosing a saw with a fence that is too thick is not advisable.

There are many factors you should consider when choosing a table saw for cabinet-building. First of all, you need to determine the size of your workspace before purchasing a saw.

Depending on the size of the workspace, you can choose the right size of the saw. Another thing you should consider is the design and portability of the saw. Aside from the blade size, the design and portability of the saw will also determine its utility.

The fence of a table saw for cabinet building should be sturdy and secure. In addition, it must be adjustable, as improper setting could result in a ruined cut or a rough finish.

Thankfully, all cabinet saws have blade adjustment mechanisms. But be sure to read all instructions and follow the instructions carefully. In short, choosing the right table saw for cabinet building is an important decision. There are many things to consider, and you’ll be happy with your purchase if you have made it yourself.

A table saw for cabinet building should come with safety features, including an overload protection device and a safety switch that’s easy to reach.

The blade guard, which is an integral part of the saw’s safety design, protects the table and any person using it. It should also come with a blade guard, which covers the blade when cutting narrow material. This feature can be a great safety feature, but it should be used with caution because the blade can be dangerous.

The Jet XACTASAW Deluxe is a great choice for those looking for an all-around table saw. Its sealed cabinet keeps out dust and is equipped with a 4-inch dust port.

In addition, it has a large cast-iron table and an extra-large 50-inch rip fence. You can find these tools online or at your local home improvement store. All models require 230V power.

Safety considerations

When using a table saw to build cabinets, there are a few safety considerations that you should keep in mind. First, you should wear proper hearing protection and eye protection.

Hearing loss is a silent killer, and it sneaks up on us without any warning. Another safety consideration is avoiding wearing loose clothing around the table saw blade. If your shirt or pants become caught, you could suffer a serious injury.

Before you begin cutting any wood, check the blade. Make sure the blade is properly positioned and that you are not standing directly in front of the blade.

Also, make sure you have a wide base so that you do not get swept up in the blade. You should also avoid standing too close to the saw, as this can cause kickback. Keeping your feet and back well away from the table saw blade will also help prevent injuries.

Before starting any project with a table saw, make sure the blade is positioned correctly. A properly aligned blade guard will prevent the blade from getting caught in the workpiece.

Additionally, you should wear hearing protection, non-slip shoes, and safety eyewear. Also, remember to read the manual and follow the proper table saw positioning.

To use the table saw, you should stand to the left of the blade and place the splitter to the proper position. Before starting the project, wait for the blade to stop spinning and check for any scraps or tools that might be touching the blade.

When cutting large pieces of wood, you should always make sure to use a table saw with a safety fence. This will help you make multiple cross cuts of the same size with the same piece.

Make sure to place a large outfeed table or workbench behind the table saw when cutting plywood. You should also wear safety glasses and earplugs when using a table saw. These precautions are essential when using a table saw to build cabinets.

Moreover, you should make sure to release the work when it passes the blade. Otherwise, you’ll invite kickback and end up cutting the part before it gets past the blade.

Also, watch out for the stock when using a table saw – it might shake or whack you. It’s a good idea to use a miter gauge to guide your stock through the blade without risking squeezing between the blade and the fence.

Frequently Asked Questions (FAQs)

1. Is a table saw necessary to build cabinets?

A table saw is not necessary to build cabinets. You can use a circular saw, hand saw, or miter saw to cut the wood for your cabinets.

2. If so, why is a table saw necessary for cabinet making?

A table saw is necessary for cabinet making because it allows for precise, clean cuts and it is much easier to control than a handheld saw. Table saws also have a variety of blades that can be used for different purposes, which makes them very versatile.

3. What are some alternative methods for building cabinets without a table saw?

Some alternative methods for building cabinets without a table saw are using a handheld circular saw, jigsaw, or a router.

Conclusion

You can build cabinets without a table saw, but it will be more difficult and time-consuming. A table saw will make the process easier and faster, and produce better results.