Last Updated on August 20, 2022

Cutting a straight line with a scroll saw is nearly impossible. Several common causes can be addressed. This article will discuss adjusting the tension on the blade, changing the blade, and avoiding the pitfalls of improper tension.

Following this advice, you’ll be on your way to making straight cuts with your scroll saw. Here are some other tips to help you avoid these common mistakes. If you’re still having trouble cutting straight lines, consider reading this article.

Getting a straight cut with a scroll saw is nearly impossible

Getting a straight cut with a circular saw is a challenging task, and using a scroll saw can be a difficult process. The circular saw blade is designed to cut material that is thin, so cutting material with thicker teeth will place too much strain on the motor, affecting speed and quality of cut.

Its smaller blade size also makes it difficult to cut straight lines, making it impossible to produce graceful curves. The circular saw blade, however, can cut thin and delicate stock, and is best for general scroll work.

Before using your scroll saw, it is important to understand the physics of the blades. Compared to circular saw blades, pressed blades are prone to veer, so make sure you choose a suitable one and adjust tension accordingly.

Straight cuts can be hard to produce on a circular saw, but with practice and proper technique, straight lines can be achieved. Once you get the hang of it, you can cut almost anything with a circular blade.

Because a scroll saw has a frame that supports the top and lower sections, it needs a certain amount of clearance to get a straight cut. This clearance is commonly known as the throat.

It is not possible to get a straight cut with a scroll saw, but you can make a curve and angle through the length and width of the wood with the tool. This makes it a great choice for many projects, such as planter boxes and trim. You can also use the saw for projects where you don’t need intricate detail.

One disadvantage of a scroll saw is that it can be difficult to make a straight cut on different materials. A scroll saw can handle wood, but it cannot cut metal.

A band saw is a better option for many types of projects. A band saw can be used for furniture, shelves, and trims. But if you are working on a large item that doesn’t need detailing, a scroll saw is the ideal choice.

Common causes of blade twisting

If you’re having trouble cutting wood with your scroll saw, it may be due to a few common causes. These issues can include excessive tension, “hogging the wood” with too much pressure, and rust.

These issues are easily resolved, but you should be aware of some common causes of blade twisting on a scroll saw. To prevent your scroll saw from experiencing this problem, use a white candle to lubricate the blade.

Another common cause of blade twisting is the incorrect way that the blade is installed on your scroll saw. It’s important to install the blade properly, and this can be easily done by following these simple guidelines. You should always use gentle forward pressure when operating a scroll saw.

Make sure that the blade is installed in the correct position before starting to cut. If the blade appears to be turned upside down, the project’s top is probably too fuzzy. Check to make sure that the crown teeth of your two-way blades are pointing downward.

One of the common causes of blade twisting on a scroll-saw is improperly lubricated. If the blade is not properly lubricated, it will corrode or break. You should also check the blade tension to make sure that it matches the thickness of your material.

While this might be a temporary fix, it can have long-term consequences, including serious injuries. To prevent these problems, you should always use a high-quality scroll-saw blade.

If your scroll saw blade twists frequently, you need to know how to fix it. Changing the blade should not be difficult. Using a manual scroll saw requires a skilled technician.

You can also consult online forums to find tips. Always read the instructions and watch videos posted by other scrollers. If you’re not sure how to change the blade on a scroll saw, a good dealer will be more than willing to demonstrate how to do it.

Correcting blade tension

One of the most common causes of a scroll saw not cutting straight is a faulty blade. This problem often occurs when the blade is too loose or too tight. If you hear a ringing, humming, or musical noise, it is likely that your blade is too loose or too tight.

In either case, you will probably need to adjust the blade tension. Luckily, there are some troubleshooting tips that can help you solve this problem.

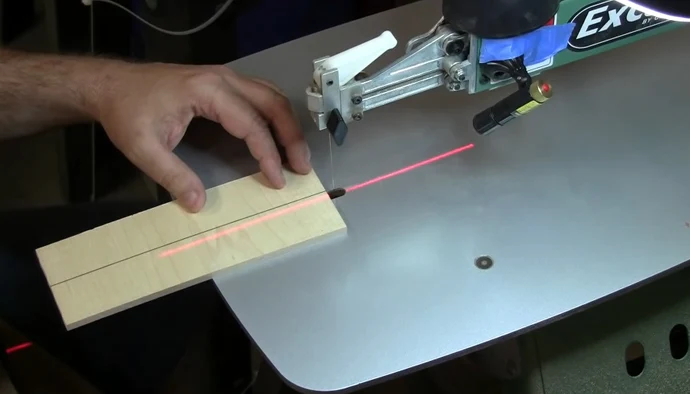

The first step in fixing a scroll saw that’s not cutting straight is to make sure the blade is not touching the side guides. This will cause the blade to veer. In some cases, a pressed blade will veer more than a ground one.

The amount of blade compensation you adjust depends on how you use your saw. Straight lines are the hardest to cut on a scroll saw, but practice will improve your results.

Another solution is to add magnification. It will give you extra precision and reduce eye strain. Head mounted magnifying glasses or a scroll saw lens will provide magnification.

Another option is to purchase a magnifying LED work light. These lights provide a better lighting source and can easily be relocated if needed. Some lights come with a magnetic or clamping base for secure attachment. After you’ve tried the tips above, you can finally use your scroll saw to make straight cuts.

The blade tension of a scroll saw is critical in achieving a smooth cut. Without proper blade tension, the blade may drift, making it difficult to achieve the desired results.

If this is the case, your scroll saw is likely not cutting straight. Regardless of the cause, the first step is to correct the blade tension. When it’s not set properly, the blade will likely drift. Always be sure to feed your workpiece at an angle.

Changing blades

When using a scroll saw, sizing the blade is an important step. There is a well-established system for blade size ranging from #12 to zero. The larger the blade, the more durable it will be.

However, you should never use a large blade on a thin piece of wood. Smaller blades may break easily and can be difficult to manage in tight spaces.

You can also reduce vibration by using a dampening agent. You can also use a counterweight to hold the blade in place and to reduce the vibration.

If you can’t afford one, try using five pounds of wood or metal. A mounting board can also help reduce vibration. This way, you can safely cut wood or aluminum. You can also cut stock at a slight angle of two to four degrees.

There are several types of blades you can use with a scroll saw. Crown tooth blades are the most common, and they have teeth that face up and down.

Crown tooth blades are ideal for smooth cuts on plastic. Spiral bits are made of steel and are best for cutting objects with sharp angles or with tight radius corners. Make sure to wear protective eyewear when using a scroll saw, as the blade can break easily.

While changing blades on a scroll saw is an essential skill to achieve the best cuts, there are many things you need to consider. First, you should understand the manufacturer’s recommendations.

These recommendations are often part of the manual or online tutorials for your scroll saw. Then, you can select the blade that best suits your needs. Make sure to choose a scroll saw that is easy to use and has blades that can be changed quickly and easily.

Dust collection

If you’re working indoors and using a scroll saw, two of the biggest problems are dust and noise. While scroll saws do not generate large amounts of dust, they can still create a considerable amount of sawdust when sanding or cutting.

Here are some ways to keep the dust in your shop under control. Using a shop vac to collect sawdust while cutting is an effective option for most scrollers.

A dust collection jig is a cheap way to collect dust while cutting. These devices are made of PVC and hook up to a shop vac or a large dust collector.

The jig collects dust and chips under the saw bed, and is connected to a smaller hose for extraction. They require a bit of assembly, but do not add much bulk to the machine. While this solution may be easier, it can be more involved to install.

The Shop Fox W1872 features a convenient dust collection system that makes changing blades a snap. The saw comes with an integrated bevel scale view-finder, variable speed control, and an on/off switch.

Unlike traditional scroll saws, it also has a dust blower and LED light. This tool gives you a professional-grade feel. It also includes 10 replacement blades. If you’re working with thicker wood, a band saw may be better for the job.

While cutting with a scroll saw, make sure to release the blade tension before using it. This way, the blade will not be forced into the stock, which may cause damage to the blade and reduce the accuracy of the cut.

Besides, it’s better to feed the stock slowly. Slower feed rates produce a smoother cut and are less important on harder woods. Once you’ve installed the blade correctly, check the tension on the blade and make sure that it’s not too tight.

Frequently Asked Questions (FAQs)

1) What can I do to make my scroll saw cut straight?

There are a few things you can do to make your scroll saw cut straight. First, make sure that the blade is properly aligned with the table. Second, make sure that the blade is tensioned correctly. Finally, use a straight edge to guide your cuts.

2) How can I fix a crooked scroll saw blade?

If your scroll saw blade is crooked, you can fix it by adjusting the blade tension.

3) What are some tips for using a scroll saw?

Here are a few tips for using a scroll saw:

– Make sure the blade is properly aligned with the table.

– Make sure the blade is tensioned correctly.

– Use a straight edge to guide your cuts.

Final Words

There are a few possible reasons for why your scroll saw is not cutting straight. The blade might be dull or damaged, the saw might be out of alignment, or you might be using the wrong type of blade. If you’re not sure what the problem is, it’s best to take your scroll saw to a professional to get it fixed.