Last Updated on August 14, 2022

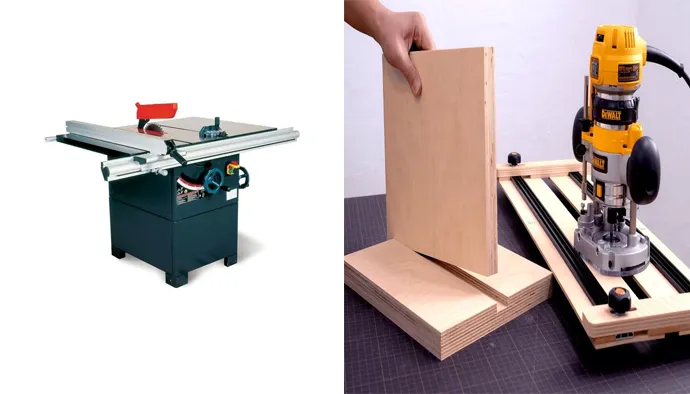

When it comes to cutting a dado joint, there are some benefits to using a table saw. You can control the width of the slot and the depth with straight bits and stacked blades.

And a table saw can save you money by eliminating the need to purchase an expensive router. However, both tools have their shortcomings. Here are some things to keep in mind when deciding which to use for your dado cutting needs.

Cut a dado joint with a table saw

When deciding between a router and a table saw, it’s important to note that routers are far less expensive. Nonetheless, they are more difficult to use.

When comparing routers and table saws, the benefits of routers are clear: they produce cleaner cuts and better consistency in dado depth.

Moreover, you can save money by using an undersized router bit, as a four flute end mill is much cheaper than a router bit. Moreover, a router is much safer to use than adjustable or stacked dado blades. However, you shouldn’t get too hung up on measurement increments.

The table saw can be used to cut a dado joint, but you must remember to clamp the workpiece while you are cutting. Another disadvantage of a table saw is that it will vibrate a lot when cutting a dado joint. Moreover, you may need to make several passes to cut a dado, which will give you a clean dado joint.

For professional projects, a table saw is better than a router. It offers a wider range of cutting options and can cut a dado joint with a single blade.

A good table saw comes with adjustable dado stacks, a wheeled stand, dust collection port, and a reversible throat plate. Once you know which tool is better for your project, you’ll know which one suits your needs best.

The table saw’s dado cutter is quick and easy to use, but the router’s cutters are much more precise and clean. Moreover, you can use a router to make stopped dadoes as well.

Its versatility makes it better than the table saw, and any router can handle the job. So, it’s worth the money. Decide which tool will best suit your needs.

When choosing a dado saw, make sure you consider the depth of the dado you’re cutting. Generally, it’s recommended to keep the blade height consistent with the depth of the final dado.

Otherwise, you’ll end up with an inaccuracy in the joint. You should also take into account the blade’s length and width, and make sure it fits the size of the mating piece of wood.

The routers are more portable. But, routers are still more efficient when it comes to a wide variety of woodworking projects. But they’re not always better for making precise cuts.

The table saws are the best tool for large materials, and can also be used to cut dado joints. The dado blade is a handy addition to a table saw if you’re looking to save space.

Table saws are typically heavier, more portable and more versatile than routers. The table saw’s dado blades and router bits are designed to cut wood, and the router’s metal bits are used to cut the wood.

A table saw, on the other hand, is a heavy piece of equipment that is often used to make dado joints. However, when comparing routers and table saws, consider the benefits of each tool.

Control the width of a dado slot with stacked blades

Dado blades are a common part of table saws and routers. They are blades that have different widths, and are installed in the saw like any other blade.

For example, a set of four dado blades will cut a half-inch wide slot, and each additional blade adds an eighth-inch. The blades are usually held together by a nut on the saw’s shaft. If you need a wider dado slot, you can add an extra blade, or shim it with a shim.

When cutting a dado slot, the width of the slot is determined by the depth of the dado set, and the width of the stock. To control the depth of the dado slot, use a steel rule to measure from the top of the blade to the tabletop.

This measurement should be one-third of the thickness of the stock. Once you know the depth of the dado, you can use the straightedge to guide the blades in the desired path.

Dado blades come in a variety of styles and can be used for a wide variety of tasks. The Freud Dado Set, for example, features a dial-a-width set that allows you to precisely adjust the width of a dado slot with no shims.

On the other hand, a “wobble” dado set will produce a dado slot that has rounded bottoms, which is a bad idea for woodworking, but might be fine for rough-carpentry tasks.

A dado joint is a common method of connecting woodstock. A dado is a groove cut into one piece of wood that fits into another.

A bookshelf builder, for example, might cut a 3/4-inch wide dado groove and then glue permanent shelves into it. These types of joints utilize slots and are especially useful in cabinet and bookshelf construction.

A dado set requires a backer board to prevent tear-out. For a dado cut, you should carefully feed the workpiece over the blades, as it removes a significant amount of wood.

A lot of wood will be removed during the dado cutting process, making the saw work harder. This is why a backer board is a necessary tool for dado cutting.

Controlling the width of a dado slot with multiple stacked blades on a table saw is easy with the right tool. There are many types of dado blades to choose from, and they are all useful for a variety of tasks.

With the right combination of different blades, you can create a dado slot that is precisely the right size for your workpiece. The most important thing to remember is that the width of a dado slot should match its mating wood.

When using a table saw, you must install the correct throat plate. This plate prevents debris from getting into the slot, and it also allows you to change the blade to a smaller width.

You should also buy an aftermarket dado blade to get the best results. The aftermarket blades for table saws are very useful as they can make any dado slot smaller or wider.

Adjust the depth of a dado slot with straight bits

When dadoing a cabinet’s side panel, a simple solution is to use a router instead of a table saw. Routers are fixed-base machines and should not be able to cut deeper than Y* inch per pass.

A router also requires a depth adjustment setting and you must advance the cutting depth setting by Y* inch. To solve this dilemma, you can use a double-bar dadoing guide, which essentially provides a single solution. The guide also incorporates a slots spacer, which adds dimension to the panel.

Unlike a router, a table saw has a sacrificial facing that lets you adjust the width of the dado slot without using shims.

This method allows you to adjust the width without moving the workpiece, and a single clamp immobilizes the sacrificial facing. For woodworking, the most ideal depth for a dado slot is 1/4 to 3/8-inch. If you do not need a glue joint, an 1/8-inch groove will do.

Another method of adjusting the depth of a dado slot is to use a straight bit. A 3/4-inch straight bit will create a dado slot slightly wider than the thickness of 3/4-inch plywood. A 1/2-inch straight router bit will accomplish the same result.

You can then use the same technique to cut a dado slot with a straight router bit, but make sure to adjust the bit speed to reduce the risk of burning the piece or prematurely dulling the router bit.

A dado blade made for a table saw will create a groove in any size of wood. The depth of the dado slot will depend on the height of the dado set.

If you are making a T-slotted wall panel, you’ll need a dado set that is half as deep as the thickness of the plywood. To adjust the depth of a dado slot with a router, you’ll need a steel rule that measures from the tabletop to the top of the blade.

If you’re planning to cut small dado slots and grooves, a router is a better option. Both of these machines are versatile and will help you complete a variety of woodworking projects.

For large-scale jobs, a table saw will provide the best results. It is also easier to set straight bits on a table saw and will fit a dado blade into the slot.

A table saw can be used to cut dado joints, but it is also a good idea to have a backer board to prevent tears. A table saw with a zero-clearance throat insert will protect the blade from the wood surface while feeding the workpiece over the blades. This will reduce wastage and make the saw work harder, creating more resistance.

Frequently Asked Questions (FAQs)

1.What is the difference between a table saw and router for making dados?

A table saw is a larger, more powerful tool that is typically used for making straight cuts. A router is a smaller, more precise tool that is typically used for making curved or intricate cuts.

2.Which tool is better for making dados, a table saw or router?

It depends on personal preference and the specific project requirements. Some woodworkers prefer using a table saw for making dados, while others find that a router is easier to control and produces cleaner results. Ultimately, it is up to the individual woodworker to decide which tool is best for their needs.

3.What are the pros and cons of using a table saw vs router for making dados?

There are several pros and cons to using a table saw vs router for making dados.

A table saw is generally more accurate than a router, so if precision is important, a table saw is the better choice. Table saws are also typically easier to set up and use than routers.

However, routers can create cleaner, smoother cuts than table saws, so if aesthetics are important, a router is the better choice. Routers also tend to be less expensive than table saws.