Last Updated on February 6, 2023

When it comes to protecting your concrete surfaces, you may be wondering whether the best option is to roll or spray concrete sealer. Both methods offer certain advantages and disadvantages and it’s important to consider various factors when deciding which is right for your project.

This blog post will explore the pros and cons of each method as well as some of the key factors to weigh while making your decision, such as surface area to be covered, cost involved with each option, level of expertise needed, availability and accessibility of equipment, weather conditions, speed required for completion and aesthetic quality desired.

Advantages and Disadvantages of Rolling vs. Spraying Concrete Sealer

Advantages of Rolling

Greater Control Over Thickness

When comparing the two methods of applying a concrete sealer, rolling offers a greater level of control over the thickness of the sealant. Spraying is only able to apply a thin coat of sealant evenly across a surface, while rolling offers more precision and allows for thicker applications in certain areas.

This can be especially useful when sealing large surfaces or areas that require additional protection from moisture or other elements.

Rolling also makes it easier to apply the sealant in layers, meaning that each layer can be thinner than if it were sprayed on all at once. This allows for better coverage and longer-lasting protection against water damage, dirt, and other debris.

Additionally, when looking for specific aesthetics or texture, rolling can be used to achieve desired effects by carefully controlling the speed and angle of application with each layer.

It is Easier to Repair Any Mistakes

Another advantage of rolling over spraying is that it is easier to repair any mistakes that may occur during application. With spraying, if an area is missed or not sufficiently covered then the mistake must often be fixed by re-applying the entire coat – which can prove costly and time consuming if multiple coats are needed for adequate protection.

With rolling however, mistakes can easily be rectified by simply adding another layer of sealant over affected areas without having to re-apply everything else again – saving both time and money on corrective measures post-application.

Less Expensive

Finally, when compared with spraying as an application method for concrete sealers, rolling tends to be much less expensive in terms of materials needed and labor costs associated with installation.

Spraying requires special equipment such as air compressors and gaskets which come at an additional cost – something that’s not required when applying with a roller (though additional tools such as a brush may still be necessary).

Plus due to its simplicity when compared with spraying, it often takes less overall time (and therefore money) to complete a job using this method so its definitely worth considering if you’re looking for a cost-effective solution!

Disadvantages of Rolling

More Time Consuming

Rolling a concrete sealer on a large surface requires more time than spraying it. This is because the roller covers less area with each pass and takes more effort to move the roller up and down, as opposed to the even spray of a paint gun.

Additionally, when it comes to complex surfaces such as driveways, patios, and walkways, spraying offers many advantages that rolling does not. It is much faster and easier to spray around curves, corners and other hard-to-reach areas, whereas rolling can be significantly more time consuming.

Can Create Uneven Areas or Streaks in Cladding Applications

When using a roller for cladding applications such as painting bricks or stonework, the risk of unsightly streaks or uneven areas may be higher than when using a spray gun. This is because it’s difficult to create an even coat of paint with a roller on these kinds of surfaces due to the texture and irregularities in the bricks or stones.

Even if you try to use thinner coats of paint, it can still be difficult to get an even finish without visible inconsistencies in some areas. Therefore, spraying might be the better option for this kind of application as it provides an even coat of paint which does not leave any visible streaks or inconsistencies behind.

Difficult to Achieve Professional-looking Results on Large Surfaces

Due to the aforementioned reasons mentioned above, it can also be difficult to achieve professional-looking results when using a roller on large surfaces such as driveways and patios.

As much finesse is required while working with less coverage per pass compared with Spraying Concrete Sealer, imperfections such as thin lines between passes or unevenness in certain areas often appear unless one is particularly experienced at rolling techniques.

Furthermore, if you don’t have access to proper tools; like extension poles for hard-to-reach areas, then achieving professional results can become even harder.

In addition, spraying ensures that all areas receive equal amounts of sealer so that no area will dry out faster than others; however this cannot necessarily be guaranteed when using rollers due to variations in pressure among different parts of the surface.

All these factors combined can make spraying concrete sealer preferable over rolling for large surface applications if you wish for professional looking results quickly and efficiently.

Advantages of Spraying

Faster Application Process Than Rolling

Spraying concrete sealer is much faster than rolling it on due to the fact that spraying covers a much larger area in a much shorter amount of time. Spraying can easily cover an area of several hundred square feet in just minutes, while rolling would take hours to achieve the same results.

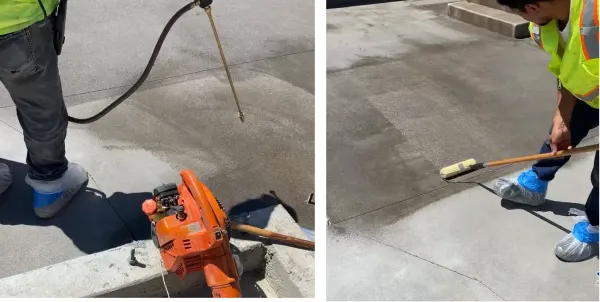

The fact that spraying can be done with an airless sprayer or HVLP sprayer also makes it relatively easy to do and not overly labor-intensive. Furthermore, with a good spray pattern and even coverage, spraying offers better quality results than rolling could achieve.

Can Achieve Even Coverage on Larger Areas Quickly and Easily

Spraying concrete sealers allows for even coverage on larger areas quickly and easily compared to rolling. With the quicker application process mentioned above, it’s also easier to apply multiple coats more quickly and efficiently when using a spraying method as opposed to rolling it on.

Furthermore, because sprayers are able to evenly distribute the concrete sealer onto all surfaces within the covered area, there is less risk of leaving some spots unprotected or uncoated than when using a roller. Additionally, since sprayers can produce finer particles of sealant than a roller does, there is less waste produced during application as well.

Ideal for Applying Multiple Coats in a Short Amount of Time

Spraying concrete sealer is ideal for applying multiple coats in short amounts of time because it’s so fast and efficient. Not only does this allow you to get the job done quickly and move onto other tasks, but it also reduces any potential disruption caused by construction or repair work because the duration of application is shortened so significantly.

With each coat being applied so quickly and uniformly, you’re also sure that each layer will adhere properly before moving onto the next one which ensures better protection overall for whatever surface you’re sealing against weather or other damage.

Furthermore, since most sprayers today have adjustable pressures settings and nozzles which allow you to customize your coverage design rather than worrying about manually covering every nook and cranny – it makes using them even more beneficial when trying to finish jobs faster without sacrificing quality.

Disadvantages of Spraying

Messier Than Rolling

Spraying concrete sealer is undoubtedly messier than rolling. The most common way to spray a sealer is by using an airless sprayer, which creates a lot of overspray. This means that the sealer not only gets onto the surface you’re spraying but also onto surrounding surfaces and areas.

This makes it difficult to control where the sealer will go and can often lead to having to clean up afterwards. Additionally, when spraying concrete sealers, they usually contain solvents or other chemicals that can be dangerous if inhaled or come into contact with skin, so extra precautions must be taken when spraying concrete sealers.

Another disadvantage of spraying over rolling is that it requires more skill in order to achieve a professional finish. As such, it’s not suitable for DIY projects as any mistakes made while spraying could end up costing more time and money in order to fix them.

You’ll also need specialized application equipment such as an airless sprayer, which can be expensive to purchase and maintain. Not only that but you’ll also need appropriate safety gear like masks and respirators in order protect yourself from fumes created by the solvents in the product being sprayed.

Requires Specialized Application Equipment and Knowledge/Skills

Spraying concrete sealers requires specialized equipment and knowledge or skills in order to do it properly. As previously mentioned, you’ll need an airless sprayer along with other accessories such as hoses and tips in order to get the job done right.

Not only will these items cost money initially for purchase but they will need regular maintenance as well in order for them to stay in top shape for maximum performance levels. If not taken care of properly then this could result in uneven coverage or a sloppy finish when applying the concrete sealer.

Additionally, even though you might own all of the necessary equipment needed for applying concrete sealers, unless you have experience doing this type of work you won’t be able to achieve the desired results that come with practice and familiarity of how everything works together harmoniously.

More Expensive (Both Purchase Price And Operating Costs) Than Rolling

Not only does spraying require special application equipment but it also costs more both upfront and throughout its use compared to rolling due to associated costs such as labor hours needed for completing a job as well as additional supplies like replacement parts for older machines because of their wear and tear over time from being used regularly .

The increased cost comes from needing more materials on hand since larger quantities are used when spraying than when using a roller or brush due to loss from overspray and accidents during application while working at heights or hard-to-reach places where accuracy is key.

Furthermore, if there’s something wrong with one part of your machine like a worn out hose connection then this could cause issues leading to waste both financially -from having to replace faulty parts-and environmentally -from creating excess amounts of pollution during use-.

Factors to Consider When Deciding Between Rolling or Spraying Concrete Sealer

Surface Area to be Covered:

One of the most important factors to consider when deciding between rolling or spraying concrete sealer is the surface area that needs to be covered. If the project is large-scale, then it would be more cost-effective and time-efficient to use a sprayer.

On smaller jobs, a roller may be more suitable as it is less expensive and require less equipment to complete. However, if the area is uneven or has many corners, then a sprayer may provide greater coverage with a neater finish than a roller which could create an uneven surface.

Cost Involved with Each Option:

The cost of each option should always be taken into consideration when deciding between rolling or spraying concrete sealer. Rollers typically require fewer materials and less equipment than sprayers so they tend to be more economical than their counterpart.

Additionally, rollers are easier to use and therefore require less expertise so labor costs are usually lower as well. On the other hand, sprayers have greater reach so they can cover larger areas faster, meaning fewer personnel and time needed for completion which could potentially save money in the long run.

Level of Expertise Needed:

Another factor to consider when deciding between rolling or spraying concrete sealer is the level of expertise needed for each option. Since rollers are simpler tools with minimal moving parts, they are generally easier to use than sprayers which can be complex machines requiring special training in order to operate safely and efficiently.

Therefore, if you’re working with an inexperienced crew who doesn’t have experience using heavy machinery or operating complex equipment then it might be best to opt for rolling rather than spraying in order not to risk any potential damage or injury from mishandling the equipment.

Availability and Accessibility of Equipment:

Before choosing one method over another for sealing concrete, take into account whether you will need specialized equipment such as pumps and hoses for spraying or just a simple roller for rolling on the sealant.

If specialized equipment like this is not readily available at your location then you may need to factor in rental fees or shipping costs depending on where you source them from; whereas rollers can usually be found at most hardware stores quite easily and don’t involve any additional costs besides materials needed for completion of the job.

Weather Conditions:

Weather conditions should also play an important part when deciding between rolling or spraying concrete sealer because extreme temperatures can affect how quickly and evenly it dries after application; especially when using a sprayer as high winds can cause overspray which could result in wastage of product as well as extra clean up required afterwards which would extend your timeline creating further delays in completion of the project.

In general, hot temperatures accelerate drying times while cold temperatures slow them down; however, it’s always best practice regardless of what method you choose ,to apply sealant only when temperatures remain comfortable throughout both application and curing processes in order avoid any potential issues along the way due to temperature fluctuations outside your control

Speed Required for Completion:

Depending on how quickly your job needs completing there are several things that need considering before making your decision between rolling or spraying concrete sealer.

Firstly consider whether time constraints will allow waiting until conditions become suitable if they aren’t currently favorable enough ,then think about what kind of coverage rate each method offers (sprayers usually offer quicker results due greater reach) followed by manpower levels involved(as more personnel often means faster completion) finally look at how much extra prep work may need doing prior too applying either method (for example if surfaces aren’t completely cleanse then this may hinder overall speed).

Aesthetic Quality Desired :

Last but not least aesthetic quality desired should also come into play when deciding between rolling or spraying concrete sealer because each one produces different results; Sprayers tend create an even smooth finish over large areas whilst rollers leave behind textured look providing better grip -So if aesthetics are top priority then you should definitely take this into consideration before opting for either one according too whichever style better fits your design scheme/preferences !

Can you put too much sealer on the concrete?

Yes, you can put too much sealer on concrete. Excess sealer can actually cause more harm than good because it will puddle in low spots, not allowing a proper bond between the slab and the sealer. This can lead to peeling, flaking or delamination of the slab surface as well as discoloration over time.

Generally speaking, one coat should be sufficient for most applications; however, some products may require multiple coats for more demanding applications like driveways or pool decks.

What is the best time to seal the concrete?

The best time to seal your concrete is when it has completely cured-generally between 30-90 days after installation. If you are sealing an existing slab that was previously sealed, wait until all traces of previous sealers have been removed before applying a new layer. Applying a new coating over an old one will reduce its effectiveness and performance over time as they will not properly adhere together.

Is one coat of concrete sealer enough?

In most cases one coat of roll or spray applied concrete sealer should be enough for protection against water penetration and other common stains; however certain applications such as exterior driveways or pool decks may require additional coats for complete protection from more extreme weather conditions like freeze/thaw cycles or intense sunlight exposure.

Once again it’s important to read and follow the manufacturer’s instructions closely regarding how many coats are recommended for your particular application.

Conclusion:

Ultimately, the choice between rolling or spraying concrete sealer really comes down to what fits best with your goals and budget. Rolling is generally considered a more cost-effective option that provides even coverage over large areas at a fast pace, but it requires more expertise than spraying.

On the other hand, spraying can provide better protection against wear and tear from chemical damage or freeze/thaw cycles in climates prone to extreme weather conditions but requires specialized equipment and more time for application.

Ultimately there is no one-size-fits-all answer – both rolling and spraying have their own unique advantages that may fit certain projects better than others. It’s important to keep all of these factors in mind when choosing a method for protecting your concrete surfaces.