Last Updated on August 18, 2022

If you’re thinking about purchasing a scroll saw, you might be wondering how to keep scroll saw blades from breaking. There are several ways to prevent this from happening.

Here are some tips: Choose a high-quality blade, lubricate it, use a blade backup, and follow manufacturer recommendations. This article will help you determine which blade type and style you should purchase. After reading it, you’ll have a better understanding of how to care for scroll saw blades.

Plain-End blades

If you want to prevent your scroll saw blades from breaking, you need to change the type of scrolling blade you’re using. There are several types of scroll saw blades, including crown and spiral.

Crown blades cut up and down while spiral blades cut sideways. Spiral blades can cut in any direction. When changing the type of scroll blade you use, make sure you’re following these simple steps to avoid blade breaks.

Pin-End scroll saw blades have pins on both ends. Pin-end blades need a cross piece to install them, while pin-less blades simply connect into slots.

These types of scroll saw blades are becoming increasingly common in modern saws. In addition to the two types of blades, most scroll saws come with a standard-tooth blade. Standard-tooth blades have an even spacing of teeth and are one-sided.

While you’re changing the plain-end scroll saw blade, you should always remember to use the correct size of the blade. Some blades are too thin for the job they’re designed for, so you should use the right one.

When changing the blade, you can either change the type or size, but make sure the one you’re using is appropriate for the task you’re performing.

When choosing the right size of plain-end scroll saw blades, be sure to read the number on the bottom of the saw. Higher numbers are thicker, and thinner blades are thin.

Although a higher number may look thicker, it’s not as durable and won’t cut as accurately. Thinner blades will easily break, especially on tough materials. In order to keep your scroll saw blades from breaking, you should select the correct blade size and type for your project.

When you’re changing the blade, it’s important to make sure that the teeth face outwards. Plain-End scroll saw blades have more teeth, but they’re also more expensive.

A typical five-inch blade has six to eight teeth. While they’re cheaper than spiral scroll saw blades, they’re still better for most jobs. You can buy plain-ended scroll saw blades at your local hardware store.

Spiral blades

When you use a scroll saw, it is important to make sure that the spiral blades do not break easily. The blades are extremely delicate, and choosing the right one can make a huge difference in the results of your scroll saw project.

The wrong blade can lead to uneven cuts or a difficult scroll art pattern. To avoid such problems, Holz Brothers carries a range of spiral blades in their product line.

The first step in keeping spiral blades from breaking is to adjust the tension on the saw. If you don’t make the adjustment properly, the blade will break too easily.

To do this, you can either use a lever or screw, depending on your scroll saw. Make sure to check the manufacturer’s instructions for your specific model before making adjustments. Alternatively, you can purchase spare spiral blades at your local hardware store.

Another step in keeping spiral blades from breaking while using a scroll saw is to check the blade holder before use. If the blades are rusted, you can save them by soaking them in WD-40 or by slowing down the machine.

However, you should make sure that you maintain control over the machine to avoid any potential breakages. When cutting wood, make sure that you always use the right blade size for the project.

Before using a spiral blade, make sure you have a plan to work on your project. Different wood types have different requirements.

A single-piece plywood is easy to cut, while a thick piece of oak needs a different blade. Also, soft woods, such as cedar, are more forgiving. When you are just starting out, experts recommend soft woods for practicing, because they break less easily.

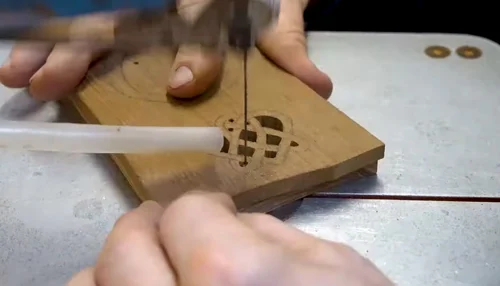

Another way to prevent spiral blades from breaking when using a scroll saw is to cut across the grain. By doing this, you minimize the friction and reduce the possibility of bumping your wood. Another way to prevent the blade from breaking is by cutting the material in layers.

This will minimize the amount of friction between the blade and the work and will make it easier for you to attach the patterns to the stock.

Using a blade backup

If you use a scroll saw often, chances are that you have experienced a broken scroll saw blade at some point. When you are using a scroll saw, you need to make sure that you’re cutting wood at the proper rate or your blade will break.

After about 10 to 50 minutes, the blade will no longer be cutting wood effectively. Using a blade backup can help you to keep your scroll saw blades from breaking.

While replacing a scroll saw blade isn’t particularly expensive, it can be a hassle and costly. It can also interrupt your work flow and make you second-guess your abilities.

In addition, you may end up in a situation where you have to go to the store to purchase a new blade. In such a situation, you risk getting hurt. Having a backup blade on hand is always a safer and more efficient alternative to having to spend hours in the shop.

If you’re cutting small components, consider reusing a larger stock. This way, you’re cutting less valuable scrap and reducing your waste. The smaller pieces, such as studs or nuts, may be too small for hold-downs.

Use double-sided carpet tape to mount the tiny pieces. Make sure to press the backup stock down so that it won’t lift up with the blade.

When using a scroll saw, it is important to remember that the blade has a limited lifespan and will need to be replaced eventually. Fortunately, there are easy ways to prevent the breaking of your scroll saw blade by using a backup blade.

The most common reason for a broken scroll saw blade is improper blade tension. A properly adjusted blade will cut the workpiece, but it’s important to check the tension of the blade.

Using a blade backup can prevent many problems, including the rusting of the tool. If your scroll saw is constantly rusting, this can result in damaged wood or a broken blade.

A rusted tool can be very dangerous. If it rusts, it will break. This is why you need to regularly maintain your scroll saw to make sure it’s working correctly.

Lubricating the blade

If you use a scroll saw, you may be wondering how to lubricate the blade to keep it from breaking. Scroll saws can get rusty and corrode, so it is important to protect your blade by lubricating it with WD-40 or oil.

You can also keep your blade in a protective tube or container to prevent rusting. However, after a while, the blade will become dull. This means that it will no longer cut as smooth and you’ll end up with jagged pieces of wood. Eventually, it is time to retire your blade.

The blade is especially vulnerable to wear and tear when you’re cutting thin sheets of metal. To minimize the risk of this, use a backing plate to protect the work surface.

A file or emery cloth will also help remove the burrs that remain. When you’re cutting metal, you’ll also leave an abrasive dust on your scroll saw, especially if you’re using a Mark V. Plastics, however, vary in density, so you may need to use a coarser blade, which will keep the workpiece from chipping or dulling.

Beeswax is a popular and inexpensive lubricant. It is good for cutting, but it can clog your sawblade’s teeth and cause inaccurate cuts.

Another alternative to beeswax is a bar of soap or candle. It’s important to rub it on the rear of the sawblade, not on the teeth. While beeswax will help prevent burns, it isn’t the ideal option for cutting delicate materials.

Another tip to lubricate the scroll saw blade to prevent breakage is to make sure that you have the correct tension. The tension rod will vary by scroll saw, so be sure to check the model before adjusting the tension rod.

If you aren’t sure, check the instructions for your scroll saw. If your scroll saw isn’t tightened properly, you may have to loosen the tension rod.

Before using your scroll saw, you should learn how to properly lubricate the blade. It is important to have the proper blade tension and avoid using too much wood.

If you don’t follow the blade’s path, it will break. If you want to avoid breaking the blade, it is best to use a reverse tooth blade. This type will eliminate splintering and will give you a smoother cut.

Frequently Asked Questions (FAQs)

1. How can I keep my scroll saw blades from breaking?

There are a few things you can do to help keep your scroll saw blades from breaking. First, make sure that you are using the correct blade for the material you are cutting.

Second, always use a sharp blade. Third, be careful not to put too much pressure on the blade while cutting. If you follow these tips, you should be able to avoid breaking your scroll saw blades.

2. What are some tips for preventing scroll saw blade breakage?

1. Check the saw blade for damage before each use.

2. Use a lower speed setting when cutting harder materials.

3. Make sure the workpiece is securely clamped down.

4. Use a push stick or other device to keep your fingers away from the blade.

3. Why do scroll saw blades break, and how can I avoid it?

There are several reasons why scroll saw blades break, but the most common one is over-tightening the blade. Over-tightening the blade puts too much tension on the blade, causing it to break.

Another common reason for scroll saw blades breaking is dull blades. When blades get dull, they can’t cut as cleanly and are more likely to break.

To avoid having your scroll saw blades break, make sure you don’t over-tighten them and keep them sharp.

4. How often should I replace my scroll saw blades, and why?

You should replace your scroll saw blades as soon as they start to wear down or get dull. This is because dull or damaged blades can cause the saw to bind, overheat, or break.

5. What are some signs that a scroll saw blade is about to break, and what should I do if I see them?

If you see the scroll saw blade starting to bend or warp, it is probably about to break. To prevent this, make sure you are using a blade that is the correct size and type for your scroll saw and that is properly tensioned. If you see any cracks in the blade, stop using it immediately and replace it with a new one.

Last Thoughts

Some possible methods include regularly cleaning and oiling the blade, using a lower speed setting, and avoiding excessively tight turns. Experimentation and paying attention to how your particular scroll saw and blade respond to different conditions is the best way to find what works for you.