Last Updated on July 19, 2022

If you want to keep your jigsaw blade straight, you may need to repair or replace a damaged blade clamp. This part is located underneath the blade support, so removing the old one will not make the new one work correctly.

After removing the old one, tighten the new one and reinstall the blade. This will fix the alignment problem. But before you start replacing the blade support, it is important to check the control bearings of your jigsaw.

Keeping a jigsaw blade straight

One of the first things you need to do when using a jigsaw is to mark out the straight line you want to cut. To do this, you can use a ruler or measuring tape.

This step is important because the vibration from the saw will interfere with your steady hands. It will also help to use a fence that is made of thick plastic or solid metal to make sure that the cut is perfectly straight.

Another step to follow in keeping a jigsaw blade straight is to choose the right type of wood-cutting jigsaw blade. Blades are available in dozens of lengths, widths, and tooth configurations.

For long, straight cuts, choose a wide blade. For curve cuts, use a narrow blade. Moreover, remember that blades with large teeth will cut faster than those with smaller ones.

Using rip guides is another way to keep your blade straight. They come with measuring tapes and built-in rulers, which makes them foolproof.

Even beginners will be able to achieve professional-looking results with these guides. If you’re unsure of where to find a rip guide, try purchasing one online. You’ll be glad you did! These guides will make rip cuts as smooth as possible.

One common problem with older jigsaws is that the blade wanders. Older ones lack guide bearings that stop the blade from moving during the cut. They may also lack guide bearings.

Ultimately, human error is another issue that can lead to a jigsaw blade wandering. You need to learn how to keep it straight. Once you master these simple steps, you’ll be able to make smooth, straight cuts in any material.

Keeping a jigsaw’s blade straight is an important step to achieving precision and fast cuts. The blade’s support pin needs to be in contact with the back of the wood while cutting.

If the support is worn, it may cause the blade to wander from the cut line. If this is the case, you can remove it with a hammer or punch. Then, you can install a new support if you wish.

The jigsaw can be used to cut both straight and curved lines. While many people assume that a jigsaw is only capable of making curved cuts, this is not the case.

This versatile tool is also capable of cutting accurate straight lines in materials. By following the correct line, you can create a straight line that is perfectly accurate. You can also use a jigsaw to cut miters, bevels, and split cuts.

Checking a jigsaw’s control bearings

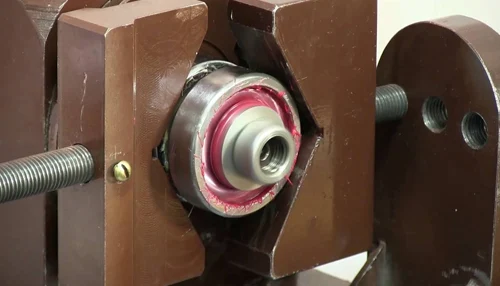

In many cases, a broken jigsaw blade can cause kickback, vibration, and jumping when cutting. To check the control bearing, unscrew the base and remove the case screws and hold down clamps, then remove the reciprocating shaft.

Examine the control bearing and replace it with a new one. Make sure to replace the O-ring as well. If the blade still swerves or skips when cutting, check the guide bearing and replace it.

You may also need to replace the carbon brush. If you don’t know how to replace the carbon brush, contact the manufacturer or an authorized service center.

You should also perform regular maintenance on your jigsaw blade. Make sure to periodically check the carbon brushes and lubricate the motor gear. It’s a good idea to replace the carbon brush every two to six months.

The control bearings are the components of the saw that allow the blade to move forward and back. They control the speed and angle of the blade and also change the type of cut you can make.

In most cases, you need a TPI of ten or twelve. The lower the number of teeth, the smoother the cut will be. However, some jigsaws have dialers that allow you to adjust the orbital action.

Another component that will wear out is the motor brushes. These are carbon and are responsible for transmitting power from the motor to the rotor.

Over time, friction will wear out the brush, rendering it useless. You can replace these brushes yourself by consulting the user manual. If they do wear out, use a new blade. A new blade will have better performance and last longer.

Besides the control bearings, you should also check the housing. The motor air vents should be clear. The shoe should be in good condition. The footplate should be sturdy and free of scratches or damage.

A steel footplate can withstand a few shocks and will not bend if dropped. Lightweight materials, however, are prone to bending after a drop.

A broken guide bearing or a blade clamp can prevent the cutting edge from being straight. Alternatively, you can replace the blade clamp by unscrewing the blade clamp.

You must make sure the new clamp tightens the blade. After replacing the blade clamp, reinstall the blade to check if the problem has been resolved. If not, replace it. If this is not the problem, try a different type of jigsaw.

In some models, the footplate is misaligned and will cause the blade to move from one side of the workpiece to the other. A misaligned footplate will result in uneven cutting, which will make the jigsaw inoperable.

If it’s a misaligned footplate, you can replace it with a shoe to ensure proper alignment. If this is the case, you can check the footplate alignment with a square or locking pliers.

Replacing a worn blade support

If you’ve noticed that your jigsaw blade isn’t cutting squarely, it’s possible that the clamp holding it in place has become damaged. Replace the blade support.

You can buy a new one from the manufacturer or purchase it separately. Install it by driving out the pin with a hammer and inserting the new one. After tightening the new clamp, you can reinstall the blade.

Your guide and control bearings are the two components that keep your jigsaw blade square to the workpiece. If either of these parts are damaged, the blade will swerve and the cuts will become uneven.

To replace the bad bearing, simply remove the support and replace it with a new one. Replace the O-ring, too. You may also need to replace the guide bearing.

Replace a worn blade support. Some models have quick releases and others require turning a small lever. Make sure that the blade fits snugly in the new support.

If you need to replace the blade support, you can try replacing the blade. The replacement blade may be the only way to get your jigsaw to cut properly again. If not, you may need to reinstall the whole machine.

Replace the carbon brush. Replace the carbon brush after every two to six months. It will reduce the likelihood of an electrical accident. The carbon brush can be replaced with a new one.

It is advisable to check the carbon brush every time you replace a blade. The carbon brush should be replaced every time you replace it, and you should lubricate the motor gear with the new one.

Replace a worn blade support. If the support is too loose, the blade may wander. If the blade is wandering, it may result in wide cuts near the saw.

Proper blade selection is key to making good cuts. You should pay close attention to tooth count, thickness, and hardness. The manufacturer of your jigsaw should provide a blade selection guide.

If the alignment of your jigsaw blade is not straight, you may need to change the blade. Some jigsaws have a tool-less system for changing the blade.

You can use a screwdriver or an Allen key to remove the blade. In most cases, you can remove the blade from the tool using a spring-loaded lever.

Another way to fix your jigsaw blade’s alignment is to replace the motor brushes. These are the first components to wear out. They transmit the power to the rotor and eventually will become ineffective.

In addition, some models are more user-friendly when it comes to replacing motor brushes, but check to see if the cord is frayed or nickged. A compromised power cord is unsafe to use.

Frequently Asked Questions (FAQs)

-What are some common causes of jigsaw blade alignment problems?

The most common causes of jigsaw blade alignment problems are incorrect installation of the blade, and damage to the blade or jigsaw.

-How can you tell if your jigsaw blades are properly aligned?

If you are using a jigsaw with a laser guide, you can tell if the blade is properly aligned if the laser is shining on the cutting line. If you are using a jigsaw without a laser guide, you can tell if the blade is properly aligned if it is perpendicular to the base of the jigsaw and the cutting line.

-What are some simple steps you can take to fix jigsaw blade alignment problems?

There are a few things you can do to fix jigsaw blade alignment problems:

-Check that the blade is installed correctly and that the teeth are pointing in the right direction.

-Make sure the blade is tight and secure in the jigsaw.

-If the problem persists, try changing the blade.

Conclusion

Some potential solutions include adjusting the jigsaw blade guide, tightening the blade, or replacing the blade entirely. If the problem persists, it may be necessary to take the jigsaw to a professional for further diagnosis and repairs.