Last Updated on January 11, 2023

There are a few key differences between caulking and fullering. While both are useful, each requires a specific set of tools and applications. This article will cover the tools and applications necessary to achieve a proper fit between the two.

It will also discuss the process and procedures for both. In addition, you’ll learn how to differentiate between the two. Below are some examples of each. Hopefully, you’ll find this information useful.

Tools

Fullering is a process that experts use to seal gaps and joints, ensuring that they will not leak or break. A forged plate is required, and fullering provides a much better finish than caulking. Fullering is best used on plates, rivets, and the edge of a plate. If you’re a DIY enthusiast, consider investing in a fullering set.

The most common caulking tool is a straight knife, but a fullering tool may be more efficient. Its width is proportional to the thickness of the plate. Many fullering tools use pneumatic pressure.

You can also purchase a backer rod, which can be used to fill gaps and joints. Both of these tools are essential for the job. If you’re unsure of which type to purchase, consult the manufacturer’s instructions.

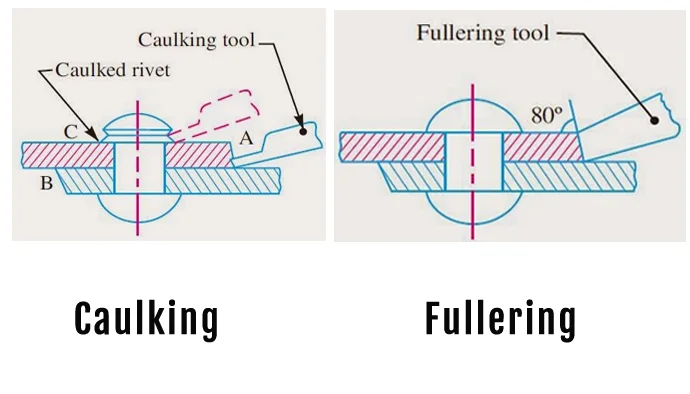

A caulking tool is a narrow blunt chisel that is 38mm in width and 5mm thick. Its edge is ground at an angle of 80 degrees. The tip forces down the joint and rivet head edges, sealing up gaps and asperities.

Typical locations for caulking include the edge of a plate in a lap joint, a strap plate in a butt joint, and the end of a rivet head.

Another tool used for fullering is the riveting set. This tool helps to bring the two plates together after riveting. Fullering tools also include a dolly to support the rivet head.

These tools also include a rivet snap, which is used to shape the rivet head. Snaps can come in various shapes to match different sizes of rivet heads, which makes it a versatile tool for sealing seams.

Process

Both caulking and fullering are methods used to seal joints in pressure vessels. Caulking is a process that creates a leak-proof joint by sealing the edges of the joint with a material that is both flexible and air-tight. A tool called a fullering hammer is used to apply fullering to the edge of a plate, rivet, or other part.

A 5mm-thick, 38mm-wide tool is used to apply fullering material to the Riveted joint. The tool’s edge is ground at an angle of about 80deg. The tool is then moved across the edge of the plate with each blow.

The tool then burrs the surface of the rivet head or joint to form a bevel that is 75 to 80 degrees. After each blow, the tool at A and B move toward each other.

Riveted joints require leak-proof joints. Riveted joints are typically made from stainless steel. Fullering makes these joints air and fluid-tight. Applications for riveted joints include pressure vessels, air receiver tanks, and ship hulls.

When using riveted joints, caulking is necessary to prevent leaks. It also helps make sure that a plate’s outer edge is beveled.

The two processes can be done manually or with the use of pneumatic tools. Caulking is performed on plates with edges that are close to each other.

The main plate is not affected by fullering and the surface finish is not as smooth as fullering. The main plate is not damaged during the procedure, but it can still be affected by an improper application. This article will cover the process of fullering and caulking.

Applications

Fullering and caulking are both techniques used to create waterproof joints. They have many applications, including air receiver tanks, ship hulls, and boilers. Backer rods are also used to fill joints.

These techniques have many benefits over caulking. Backer rods reduce caulking application time and can be more economical. Fullering tools have various advantages. Here are some of them.

Elastomeric caulk – This type of sealant is made up of polymers that have elastic properties. Because of their high flexibility, elastomeric caulk is most effective in areas of expansion and exposure to extreme weather conditions.

If you are unsure of which type to choose, consult a manufacturer’s website or ask an experienced professional. In general, you want to use elastomeric caulks in the harshest conditions.

Compound caulking: These compound sealants are used for a wide variety of purposes, including weatherproofing joints, providing structural glazing function, and creating a secure bond between two materials.

Most caulking compounds are dispensed from a manufacturer’s tube. Conventional caulking tools have a trigger-like actuator connected to a plunger. A skilled operator is required to create an aesthetically pleasing result. The bed depth should be a good match for joint performance.

In some cases, lubricant compositions are not necessary, but they are a useful aid for smoothing the caulking compound. These compounds should be applied to the exposed surface of the caulking bead.

Ideally, the user should place a lubricant composition on the finger of the manmade tool, and the lubricant will help smooth out the bead. The user should then apply light pressure to the bead to eliminate air bubbles and ensure full contact between the bead and the surrounding surface.

Procedure

Fullering and caulking are two methods used for securing joints. The former makes the joint leakproof and fluid tight. Both methods are similar in nature, and they use a blunt chisel tool that is about five millimeters thick and 38 millimeters wide with a 45-degree angle at one end.

The process of caulking a riveted joint is the same as that of fullering a bolted joint.

Before applying caulk to a joint, it is necessary to prepare the area. Before you apply caulk, make sure the edges of the plates are beveled at seventy or eighty degrees.

This is done with a hammer, or with a pneumatic or hydraulic tool. When blowing the tool, ensure that it is close to the plate and does not injure the worker. Otherwise, you might end up with an insufficient amount of material.

After applying caulk, the surface should be clean and free of debris. Do not use caulk on areas with mold or mildew because it will only encourage dirt to accumulate.

Also, the type of caulk will determine the speed of curing and its ability to withstand exposure to sunlight. The lower quality acrylic latex products contain external plasticizers that make them tacky.

Paint can be applied on top of some water-based caulks. However, a higher quality caulk will probably outlast the paint.

A proper caulk is useful for sealing gaps. It helps to weather-seal windows and doors and seal sinks, bathtubs, and showers. Follow the simple steps to caulk a gap and get an attractive final finish.

A good tool for caulking is a caulking gun or a caulk brush. Make sure to remove any debris or silicone caulk that may have built up on the surface before application.

Frequently Asked Questions (FAQs)

What is the difference between caulking and fullering?

Caulking is a waterproofing sealant that is applied to cracks or gaps in order to prevent water from entering. Fullering is a process of shaping metal by hammering it while it is hot.

What are the benefits of caulking over fullering?

Caulking is the process of sealing joints or cracks in order to prevent water infiltration. Fullering is the process of shaping or enlarging a hole. While fullering may provide a temporary fix, it does not offer the same level of protection as caulking.

What are the benefits of fullering over caulking?

There are several benefits to fullering over caulking, including:

- Fullering provides a stronger seal than caulking, making it ideal for high-pressure applications.

- Fullering is more resistant to temperature changes than caulking, making it ideal for use in extreme climates.

- Fullering is more resistant to chemical degradation than caulking, making it ideal for use in harsh environments.

- Fullering is easier to apply than caulking, making it ideal for do-it-yourself projects.

- Fullering is less likely to shrink or crack than caulking, making it ideal for long-term applications.

Conclusion

Caulking is the process of sealing a joint or crack with a waterproof material, while fullering is the process of shaping or enlarging a groove or depression.