Last Updated on July 3, 2022

Can you use an SDS drill bit in a normal ratcheting chuck? Yes, you can! SDS drill bits are spring loaded and designed to move themselves. This makes them stronger and more durable.

However, before you buy your next SDS bit, read this article to learn how it works. Once you’re done, you’ll be able to use it in any type of ratcheting chuck.

SDS drill bits are spring loaded

Despite their name, SDS drill bits are not exactly universal. Most are made of steel and may feature different coatings. Carbide tipped bits and chrome-nickel molybdenum steel are some of the most common options.

Top-quality SDS bits are made by leading manufacturers. Choosing one manufacturer will depend on the purpose of your drill and personal preference.

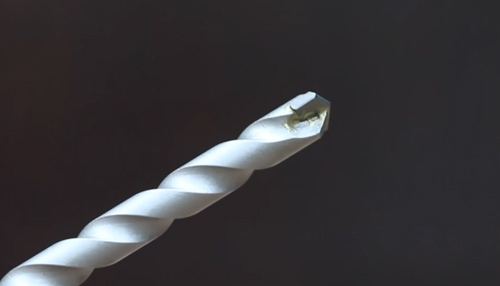

These masonry bits are designed to work in a rotary hammer drill. They are inserted into the end of the drill and held in place by twisting the chuck.

The collar then locks into place, holding the bit in place. The shank of the SDS drill bit has two slots that accept two ball bearings, holding it securely in place. Once you insert the bit, it will remain in place until you remove it from the chuck.

Choosing the right drill bit for the job is crucial. Whether you are using an SDS drill bit or a normal drill, you need to know which one will fit your needs.

You can find SDS bits for concrete and masonry and compare their advantages and disadvantages. When choosing the right bit for your project, you should also make sure that it will work with your existing drill.

In addition to that, you should consider the material you are drilling with. You don’t want to damage your drilling tools by accidentally ripping the bit from the drill.

SDS drill bits come in three different formats: SDS Plus, SDS Max, and SDS Max. The latter is the most common and is the most popular for normal masonry and concrete work.

Using an SDS Plus drill bit means that you can drill through concrete without fear of chipping or breaking the concrete. This drill is ideal for drilling into concrete and larger studs.

They are designed to move by themselves

Unlike traditional drill bits, SDS drill bits are designed to move by themselves, preventing the bit from being jammed inside the chuck.

They feature four grooves in their shank to guide the bit while it rotates, and are designed to slide in and out of the chuck without slipping. This design also allows the bit to transmit more torque and energy when drilling. Another benefit is the reduced power draw while in use.

When drilling concrete, SDS+ drill bits are designed to drill through a solid material without using an abrasive compound. The patented spiral design and groves in the shank allow the bit to hammer independently, which prevents premature bit burns.

These features also make it easier to control the bit’s position and to drill through thicker materials. This feature is not only useful for drilling through concrete, but for drilling into larger studs as well.

SDS bits come in two different sizes. The SDS Plus range is shorter than SDS Max bits, making it easier to drill small holes close to the edges.

The smaller, lighter-duty SDS plus bit reduces the risk of chipping concrete and can be used near the edges of walls and floors. The SDS Max range is longer, with long shanks for deeper embedment. These drill bits are also available in a rotary-only mode.

They are stronger

SDS drill bits are stronger than normal drill bits for a variety of reasons. The drill bit head itself is made of carbide, which helps break up concrete and other materials.

Because the carbide tip is brazed to the drill bit, it’s more durable. The same concept applies to SDS Max and SDS PLUS drill bits. However, if you’re working on a tougher project, you might want to try an SDS Max.

The SDS system was first developed in Germany, where the German word “Stecken, Drehen, Sichern” is commonly used. SDS bits are stronger than standard drill bits because the bit’s design is shaped to create additional force and torque.

This extra force can be transferred to the material being drilled. A standard drill requires you to tighten its three jaws on its smooth shank to achieve the proper angle. Then, when you encounter resistance, you must re-tighten the drill bit.

Abrasive and diamond-tipped bits can be used to drill wood and some plastics. These drill bits can also be used to drill soft plastic. While they are not as strong as HSS drill bits, they can be more flexible and stronger than normal drill bits. When you’re using a drill press, it’s better to use an SDS drill bit than a hand drill.

They are more durable

SDS drill bits have a more durable design, which helps them work more efficiently in difficult environments. They have a smaller diameter and are designed for drilling in lighter-duty concrete, as well as smaller holes, or for drilling close to the edge of the substrate.

These bits are available in various lengths, so you can choose the most suitable one for your particular needs. This article will discuss the differences between SDS Max drill bits.

SDS drill bits have a rounded tip that helps them cut through tougher materials. Their high-speed steel allows them to cut through tougher materials.

These bits are coated in carbide, which makes them more durable and reduces the risk of corrosion and overheating. Hence, you should consider investing in high-quality bits. If you do not have enough money for high-quality drills, you can opt for cheaper bits.

The hardness of the material can be measured on the Moh’s scale. This scale offers values from one to ten. Diamonds are the hardest material on Earth.

Tungsten carbide, on the other hand, has a hardness value of nine. So, SDS drill bits are capable of drilling through materials with lower hardness values. They are a better option for drilling holes in concrete, rock, and brick.

They are more secure

SDS drill bits have several advantages over traditional ones. For one, they have a larger surface area. Furthermore, they are designed for higher torque and more force, resulting in higher productivity.

Moreover, they are more secure in a normal drill because of their higher torsional strength. Consequently, SDS drill bits are recommended for drilling into concrete, which has higher density and resistance. Moreover, these bits are designed to drill through thicker substrates and larger studs.

SDS is an acronym for Slotted Drive System. It refers to a special type of chuck that generates extra force and torque. SDS drill bits are designed to work with a corresponding chuck.

This is the most common type of bit. It is suited for most masonry and concrete applications. It also reduces friction levels. SDS drill bits are available in various sizes.

SDS drills were developed in Germany. Their hammer mode is useful for drilling stone and concrete. It also has a wide flat chisel blade that can remove tile and plaster.

In addition, smaller chisels can chase blockwork and conduit. Box chasers are helpful in cutting holes. Sutch combs are also useful for preparing surfaces for coatings.

They can be sharpened

If you own a hammer drill, you may be wondering if you can use an SDS drill bit in it. It’s not impossible! The hammer drill chucks have been specially designed to accept the splines of an SDS drill bit.

The splines allow the bit to move back and forth along the drill’s shaft, which increases the strength of the hammering action.

SDS bits are hardened, unlike straight shank bits. These bits are not able to be held centrally in a normal drill chuck because they have grooves. You can cut the end of the bit to fit your normal drill, but this is only a temporary solution.

Buying the right tool will cost you a couple of pennies. You can also get a tradesperson or supplier by doing a search in your area.

However, you should never use an SDS drill bit in a normal drill. The standard drill chuck is not designed to hold this type of bit, and it will loosen and damage your drill.

This can also affect the quality of your work. If you are unsure whether you should use an SDS drill bit in your drill, make sure that you have an SDS chuck for your drill.

Frequently Asked Questions (FAQs)

1. What is an SDS drill bit?

An SDS drill bit is a type of drill bit that is used with a hammer drill. The SDS stands for “speciality drilling system” and these bits are designed for use with concrete and other masonry materials.

The SDS drill bit has a carbide tip that helps it to drill through these hard materials quickly and easily.

2. What is the difference between an SDS drill bit and a normal drill bit?

SDS drill bits are designed for use with SDS (Rotary Hammer) drills. They have a special shank that fits into the chuck of an SDS drill. The main difference between an SDS drill bit and a normal drill bit is the way that they are held in the drill.

SDS drill bits can be used in both rotary and percussion drilling modes, whereas normal drill bits can only be used in rotary mode.

Verdict

From what I can find, it seems that you can use an SDS drill bit in a normal drill, but it is not recommended. The main reason for this is that the SDS drill bit is designed to be used in a hammer drill, which has more power than a regular drill.