Last Updated on August 22, 2022

If you’re looking to drill through concrete, but are unsure of the type of bit to use, you may be wondering: can normal drill bits go through concrete?

Fortunately, there are many options, including solid carbide drill bits, tin coated bits, and hammer drills. Read on to learn more. Until next time, use the best tool for the job: a 12V cordless drill!

Solid carbide

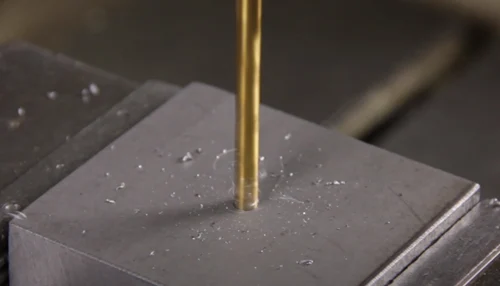

While many construction jobs require hard core drill materials like steel and concrete, some tasks require more delicate tools. Solid carbide drill bits can go through a variety of materials, including abrasive surfaces.

These bits feature a carbide construction throughout the bit’s head, and they are highly effective in drilling non-ferrous metals. Solid carbide drill bits often have a black oxide coating to retain lubricants and prevent rust.

Some bits feature a titanium nitrate coating to extend their life when drilling hard metals, while titanium aluminum nitrate offers high-speed abrasion resistance and high-temperature resistance.

The size of the drill bit’s head will depend on the application. Generally, the head of a solid carbide bit will be 1/2″ or smaller, with a single carbide cutter on both sides.

The two-cutter bit is the least expensive, but the performance will be less than stellar. A four-cutter bit will last a longer time. But you’ll need to take extra care when using a carbide drill bit.

Among its many benefits, carbide drill bits can go through concrete. Since carbide drill bits are made of a hard alloy, they are a durable choice. A patented solid carbide tip will drill through various materials, including bricks, glass, plastic, and wood.

The U-shaped groove design offers low resistance and smoother drilling. Solid carbide drill bits are available in seven sizes. Always lubricate concrete with water when drilling hard materials, such as glass.

Unlike diamond drill bits, solid carbide drill bits have high reactivity with steel. This means that they are not reversible, but are still highly durable. When used properly, these drill bits will go through the toughest materials.

But when used improperly, they may break. The only way to use carbide drill bits is to be sure that they are sharp and do not overheat. If you don’t use your drill correctly, you could risk breaking them, so be sure to follow proper precautions and only use drill bits that are designed for concrete.

TiN coated

Drill bits made from carbon steel can easily chip or dull. To prevent such damage, try to sharpen your drill bit frequently to avoid the wear and tear caused by constant use.

However, if you want to drill through concrete with speed, a TiN-coated drill bit is a better choice. It reduces heat buildup in the bit, extending its life up to five times. The coating is particularly useful for drilling through concrete and other hard-to-penetrate materials.

In addition to the titanium nitride coating, some drill bits are available in gold color. This coating makes them easier to identify. For example, Dewalt PilotPoint bits are gold-colored, a common option for drill bits.

However, machining forum posts suggest that these drill bits are a step below TiN. So, before you buy a drill bit, find out what the coating is on the bit.

In general, drill bits made from metal are the most versatile choice for drilling through any surface. However, you can also use a drill with masonry bits if you want to drill through solid concrete.

The sharper and heavier the drill bit, the greater its chances of going through a concrete-hard surface. This way, you won’t have to worry about breaking through a slab, or damaging a wall.

Aside from diamond-coated bits, there are also tungsten carbide-coated drill bits. These are also designed for drilling holes in hard-to-drill materials such as concrete, masonry, and brick.

Unlike HSS bits, diamond-coated drill bits are less likely to melt or crack their edges during the drilling process. It’s important to use a drill bit that is designed to cut through the material you’re drilling into.

Core bit

When drilling a hole in concrete, you should not use a normal drill bit. Concrete is different than metal or wood and requires different drill bits. The most common types of concrete products are poured concrete, cast-in-place masonry blocks, roofing tiles, cement-fiberboard, artificial stone, and more.

However, you should still pay attention to the depth of the hole when drilling concrete. For example, if the hole is going through the top layer of the concrete, the drill bit may shatter.

If the hole is small and you need to drill a larger hole, a diamond drill bit will be more effective. These bits have an outstanding shape, and they make smaller holes. Make sure you clean them after use and cool them frequently.

These bits also come with flutes that make it easier to remove unwanted materials during drilling. Nevertheless, these drill bits can only drill through concrete when you’re working with them. You should also keep the drill bit in a safe place while using it.

Different drill bits have different material compositions. For instance, drill bits designed for wood have different material compositions than those made for metal, concrete, and brick.

A general-purpose drill bit will usually contain high-speed steel, while those designed for concrete and brick will be made of carbon steel, chromium, or vanadium. Moreover, different drill bits can be used on different surfaces. For this reason, you should always use the appropriate drill bits for the job.

The drill point is the main part of the drill bit, which can come in several configurations, including split, screw, and conventional. The most important feature of the drill point is the angle it has.

For fast cutting, a 90-degree angle is appropriate, while a 118-degree angle will be suitable for general drilling. For boring into harder materials, you should use a 135-degree angle. The angles of the hole saws can be adjusted by varying degrees, depending on the desired cutting angle.

Hammer drill

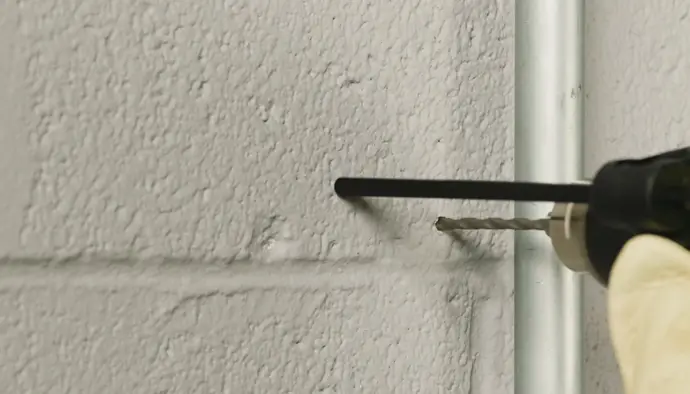

If you’re planning on drilling holes in concrete, you’ll want to mark the locations before you start. It’s important to use a steady light touch when drilling into concrete and consider the depth of the hole you’re drilling.

Never force the drill bit through the concrete as there are air pockets, pebbles and stones in it that will cause unpredictable resistance. When drilling in concrete, make sure to use a drill with a depth stop.

In addition to the three prong chuck, hammer drills also have a slotted design system and a three-prong smooth chuck. The carbide tip of a hammer drill can be damaged by extreme heat, which will reduce its ability to break the concrete.

Therefore, a hammer drill with a slotted-design system is the best choice for concrete drilling. However, it’s important to know the correct bit size for the type of concrete you’re drilling, as this will help you get the best results.

A hammer drill has several unique features. For example, a hammer drill is equipped with a depth stop, which makes it easier to measure the depth of the hole. Some hammer drills also come with a side handle that makes it easier to operate.

You’ll also find that rotary hammers often have depth stop features. These are important when drilling concrete, as you don’t want to drill through the concrete to its hollow core.

The main difference between a hammer drill and a cordless drill is the speed. The cordless drill can quickly drive screws into walls and wood, but a hammer drill is better suited for tougher materials.

A hammer drill forces its drill bit into the concrete at a high rate, digging out a hole in it. These drills are designed for occasional drilling and smaller holes. In addition, a hammer drill is designed to withstand extreme pressure.

Impact driver

If you’ve ever used a standard drill, you’ll understand how helpful an impact driver can be. Not only can you drill holes in concrete, but you can also use it to mix small amounts of cement.

While cement is a fairly thick substance, normal drills often cannot drill through it easily. An impact driver’s high torque and cutting speed allow it to easily cut through this material, and this type of drilling tool can be a great asset for a variety of different tasks.

Hammer drills are designed to drill into concrete or masonry. Hammer drills use a percussive motion to drill through masonry faster, but they can also go through concrete.

Impact drivers can also drill into concrete, though they may not go through it as quickly. However, their higher RPMs will allow them to drill more quickly. You should still pay close attention to the recommended RPM range for your impact driver to get the job done.

Another advantage of an impact driver is that it can be used to screw in large fasteners. You can use it to secure beams into a pergola, for example. You can use it for almost any job where long screws or bolts are needed.

Its powerful torque will enable you to drive through any material, including pressure-treated lumber, hardwood, and even heavy steel. The speed of your impact driver depends on several different factors.

If you need to drill through concrete, an impact driver can help. They can go through stone and concrete, but normal drills can only go so far. Using an impact driver, you can drill a large number of screws into dense materials with ease.

Make sure to use a good set of screwdriver bits when using an impact driver. This can be a great time-saver. If you don’t have a large budget, consider using one of these powerful tools.

Frequently Asked Questions (FAQs)

1. What is the difference between a normal drill bit and a concrete drill bit?

A normal drill bit is not designed to drill through concrete, while a concrete drill bit is. Concrete drill bits have a carbide tip that is specifically designed to drill through concrete and other masonry materials.

2. Will a normal drill bit go through concrete?

A normal drill bit can go through concrete, but it will take some time and effort. It is best to use a hammer drill or rotary hammer when drilling into concrete.

3. Are there any dangers to using a normal drill bit on concrete?

Yes, there are dangers to using a normal drill bit on concrete. The bit can overheat and break, or it can get stuck in the concrete.

Final Words

The hardness of concrete can vary greatly depending on the ingredients used and the curing process. However, in general, normal drill bits are not designed to drill through concrete and will quickly become dull if used on this material.